3D Printing

DLP 3D Printer with Exchangeable LEDs. A custom digital light processing (DLP) 3D printer from Monoprinter with five exchangeable visible LEDs is available: 405 nm (violet, Luminus CBT-120-UV), 460 nm (blue, Luminus PT-120-B), 525 nm (green, Luminus PT-120-G), 615 nm (red, Luminus PT-120-RA), 740 nm (far-red, Luminus, CBM-120-FR) and 850 nm (near-IR, Luminus CBM-90-IRD). Each LED contains a 12 mm2 emission surface area and a maximum current up to 30 A, with a max intensity of 24.3, 19.4, 9.7, 10.6, 7.1, and 6.4 mW/cm2 respectively. The full width at half maximum (FWHM) of each LED is 16, 20, 34, 19, 30 and 51 nm for violet, blue, green, red, and far-red light, respectively. The projector has a resolution of 1920 × 1080 pixels, with each pixel being 21 µm × 21 µm at the image plane. The minimum achievable layer thickness is 25 µm. The maximum build plane for the printer in its current configuration is 38.4 mm × 21.6 mm, and a vat with the dimensions of 56 mm × 35 mm × 25 mm (length × width × height) was used. A transparent fluorinated polymer film (Teflon FEP film, McMaster-Carr, 127 µm thick and/or PFA film, McMaster-Carr, 127 µm thick) is used as the base of the resin tank to provide a non-stick, high-temperature resistant, and flexible surface.

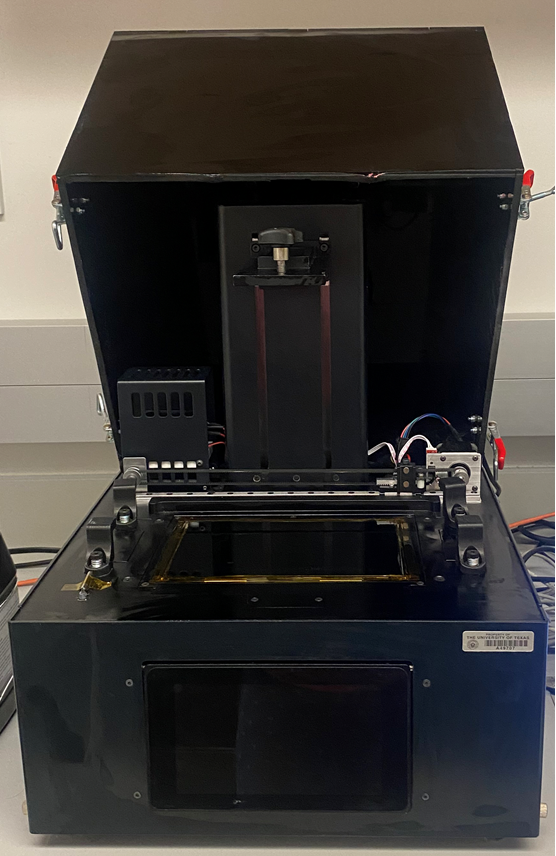

DLP 3D Printer with Exchangeable LED Arrays

(“Kramer”)

A custom digital light processing (DLP) 3D printer from Monoprinter comprises 4 sub-assembly parts: Projector 0, Projector 1, Printer, and Dichroic mount. Projector 1 houses green and red LEDs and projector 2 houses blue and violet LEDs. The four different visible LEDs are centered at 405 nm (violet, Luminus CBT-120-UV), 460 nm (blue, Luminus PT-120-B), 525 nm (green, Luminus PT-120-G), and 615 nm (red, Luminus PT-120-RA). Each LED contains a 12 mm2 emission surface area and a maximum current up to 30 A, with a max intensity of 23.5, 18.2, 7.7, and 8.2 mW/cm2, respectively. The full width at half maximum (FWHM) of each LED is 16, 20, 34, 19 nm for violet, blue, green, and red light, respectively. The projector resolution is 1920 × 1080 pixels, with each pixel being 20.7 μm × 20.7 μm at the image plane. The minimum achievable layer thickness is 25 μm and the maximum build plane for the printer in its current configuration is 39.74 mm × 22.36 mm, and a vat with the dimensions of 56 mm × 35 mm × 25 mm (length × width × height) is compatible. A transparent fluorinated polymer film (Teflon FEP film, McMaster-Carr, 127 µm thick and/or PFA film, McMaster-Carr, 127 µm thick) is used as the base of the resin tank to provide a non-stick, high-temperature resistant, and flexible surface.

DLP 3D Printer with Four Color Channels

(“George”)

This custom digital light processing (DLP) 3D printer from MonoPrinter has two built in light emitting diodes centered at 365 nm and 405 nm with maximum light intensities of 18.3 and 92.0 mW/cm2 and FWHM values of 17 nm and 20 nm, respectively. Both projectors (PDC04-365 nm & PDC04-405 nm) have a resolution of 1920 × 1080 pixels and provide a lateral resolution of 23 µm. The projections are combined through a dichroic filter (Chroma T387lp 35 x 50 x 1mm). The. vertical resolution is controlled by layer thickness, which can range from 10 µm to 300 µm. The build area is 44.54 mm × 25.06 mm. A transparent polymer film (Teflon FEP film (McMaster-Carr Cat. 85905K66, 127 µm thick), ACF film (Phrozen 254 µm thick), or Silicone film (Amazon, 200 µm thick)) is used as the base of the resin tank to provide a non-stick, high-temperature resistant, and flexible surface. Additionally, fluorinated oil (DuPont D10329494 Krytox by Chemours GPL 101 Industrial Oil) can be applied to the vat film to further prevent sticking.

DLP 3D Printer with Dual Wavelength Capabilities

(“Jerry”)

A custom single channel digital light processing (DLP) 3D printer from MonoPrinter with exchangeable light emitting diodes (405 nm, 460 nm, 525 nm, and 616 nm). The FWHM values are 15, 20, 34, and 19 nm respectively. The projection source is a LRS-WQ-VIS-LC from Visitech (part # 7000380-VIS-460), with a resolution of 2560 × 1600 pixels. Available lenses are LRS-20 (part # 6505860) and LRS 05 (part # 6502490), providing respectively 2× and 0.5× magnifications, 50 mm and 90 mm working distances, 3.78 µm and 15.10 µm pixel pitches, and 9.67 mm × 6.05 mm and 38.66 mm × 24.16 mm image sizes. The vertical resolution is controlled by layer thickness which can range from 5 µm to 500 µm. A 6L water chiller from Cloudray (CW-5200DH) is used to cool the LEDs with minimal vibrations. The maximum intensities with the LRS-20 lens are: 69 mW/cm2 (405 nm), 139 mW/cm2 (460 nm), 52 mW/cm2 (530 nm), and 55 mW/cm2 (615 nm). A transparent polymer film (Teflon FEP film (McMaster-Carr Cat.85905K66, 127 µm thick), ACF film (Phrozen, 254 µm thick), or Silicone film (Amazon, 200 µm thick)) is used as the base of the resin tank to provide a non-stick, high-temperature resistant, and flexible surface. Additionally, fluorinated oil (DuPont D10329494 Krytox by Chemours GPL 101 Industrial Oil) can be applied to the vat film to further prevent sticking.

High Power Single Channel DLP 3D Printer

(“Crazy Joe Davola”)

LCD 3D printer from Monoprinter (MONO-4K89) provides layer-by-layer fabrication of objects through in-plane illumination through an 8.9-inch monochromatic 4k liquid crystal display (3840 x 2400 pixels). The system has exchangeable light emitting diode arrays with wavelengths centered at 385, 405, 460, 520, 620, 640, 740, and 850 nm, providing a contrast of 446 and maximum intensities for these LEDs are 10.3, 11.0, 19.0, 7.5, 10.9, 12.2, 8.0, and 7.0 respectively. The FWHM values are 14, 14, 20, 33, 22, 17, 37, and 29 nm respectively. The lateral resolution is 50 μm and the vertical resolution is controlled by the layer thickness, which ranges from 50 to 300 μm. The full build area is 192 x 120 x 175 mm (length × width × height), with an optional insert available to decrease the build area to 56 mm × 35 mm × 25 mm (length × width × height). A multi-well vat can also be used and consists of six small vats with 10X10X5 mm dimensions. Standard operation provides a maximum print speed of 30 mm/hour. Digital STL/OBJ files are read, sliced, and imported to the printer using MonoWare software.

LCD 3D Printer with Exchangeable LED Arrays

(“Elaine”)

An LCD 3D printer from Monoprinter (MONO-4K89) provides layer-by-layer fabrication of objects through in-plane illumination through an 8.9-inch monochromatic 4k liquid crystal display (3840 x 2400 pixels). The system has a built-in (ultra)violet light emitting diode array that is centered at 405 nm, providing a contrast of 512 and a maximum light intensity of 7.92 mW/cm2. The lateral resolution is 50 μm and the vertical resolution is controlled by the layer thickness, which ranges from 50 to 300 μm. The full build area is 192 x 120 x 175 mm (length × width × height), with an optional insert available to decrease the build area to 56 mm × 35 mm × 25 mm (length × width × height). Standard operation provides a maximum print speed of 30 mm/hour. Digital STL/OBJ files are read, sliced, and imported to the printer using MonoWare software.

(Ultra)Violet-LCD 3D Printer

(“Newman”)

An extrusion style printer from Prusa3D supports a variety of 1.75 mm filament types (PLA, ABS, PC, etc.) with a default 0.4 mm nozzle. The build volume is 25×21×21 cm with a layer height range of 0.05 – 0.35 mm and max travel speed 200+ mm/s. The multi material upgrade (MMU2S) enables printing with up to 5 filament colors.

Original Prusa i3 MK3S+

(“Frank”)

The lab has two dual action cure and wash devices and two sealed washing containers. Control methods include a digital tube, LED indicator, and control knob. It is equipped with a rated power specification of 25W and input voltage of AC110/220V 50/60Hz. It emits UV light (405nm) via a single stand/strip of 12 LEDs centered behind the rotating platform. The front dial allows the user to select a curing time 1-60 mins. The size of the machine as a whole is 225mm(L) *235mm(W) *365mm(H), and the weight is 3.7kg. The size of the wash bath is 120mm(L) *74mm(W) *165mm(H). Maximum curing size is 140mm(D) *165mm(H). The UV blocking orange cover blocks 99.95% of UV light and must be secured in the correct position for curing to begin.